Due to the two different material has different characteristics,there are certain differences in performance between the two bulletproof products.In order to let customers to choose suitable products,I will introduce the advantage and the disadvantage of both fabrics:

1. PE Fabric

UHMW-PE is ultra-high molecular weight polyethylene. It is a high-performance organic fiber developed in the early 1980s. Together with carbon fiber and aramid, it is known as the three major high-tech fibers in the world today. It has ultra-high stability and is extremely difficult to degrade, thus causing serious environmental pollution. But it is precisely because of this property that it is an ideal material for making body armor. In addition, it has the characteristics of low temperature resistance, UV resistance, and water resistance.

In terms of defense against low-speed bullets, the anti-ballistic performance of UHMW-PE fiber is about 30% higher than that of aramid;In terms of defense against high-speed bullets, the bulletproof ability of UHMW-PE fiber is 1.5 to 2 times that of aramid.

However, UHMW-PE also has some disadvantages: its high temperature resistance is far inferior to that of aramid. The use temperature of UHMWPE bulletproof products needs to be controlled within 80°C (which can meet the temperature requirements of the human body and equipment – temperature resistance of 55°C). Once the temperature exceeds this temperature, its performance will drop rapidly. The aramid bulletproof products can still maintain a stable structure and good protective performance at a high temperature of 200 ° C. Therefore, PE bulletproof products are not suitable for use in high temperature environments.

In addition, the creep resistance of PE is not as good as that of aramid, and equipment using PE will slowly deform when subjected to continuous pressure. Therefore, equipment with complex shapes such as helmets that need to withstand pressure for a long time cannot be made of PE.

2. Aramid Fabric

Aramid, also known as Kevlar, was born in the late 1960s. It is a new type of high-tech synthetic fiber. It has the advantages of high temperature resistance, acid and alkali resistance, light weight and high strength. It has been widely used in bulletproof protective equipment. , construction and electronic equipment.

But aramid also has two fatal shortcomings:

(1) It will degrade in the presence of ultraviolet light;

(2) Easily hydrolyzed, even if stored in a dry environment, it will absorb moisture in the air and gradually hydrolyze.

Therefore, aramid bulletproof inserts and bulletproof vests are not suitable for long-term use in environments with strong ultraviolet rays and humidity, which will greatly reduce their protective performance and service life. In addition, the poor stability and short life of aramid also limit the further application of aramid in the field of bulletproofing.

The price of high-quality aramid is also higher than that of PE, which may be 30% to 50% more. At present, the bulletproof products using aramid have gradually decreased and begun to be replaced by PE bulletproof products. Unless it is in a special environment or has special requirements, such as the Middle East with high temperatures all year round, it is still recommended to use PE material bulletproof equipment.

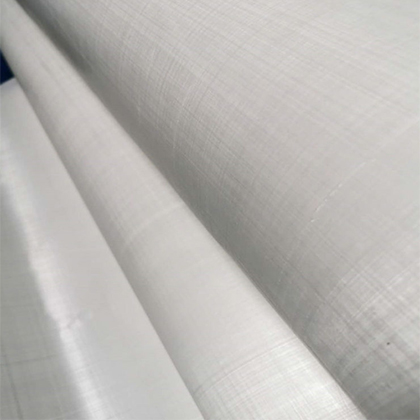

3. How To Distinguish The Two Different Bulletproof Fabric?

Firstly, you can see the color, PE is white and Aramid is yellow.And then you can touch them, PE is more flexible than Aramid.This is the most direct way to distinguish between the two fabrics.

Above is the introduction of the two bulletproof fabric,I believe that customers have a certain understanding of them, and customers can evaluate their advantages &disadvantages to choose products that suit them.